Efficient blowing with compressed air in the steel and aluminum industries

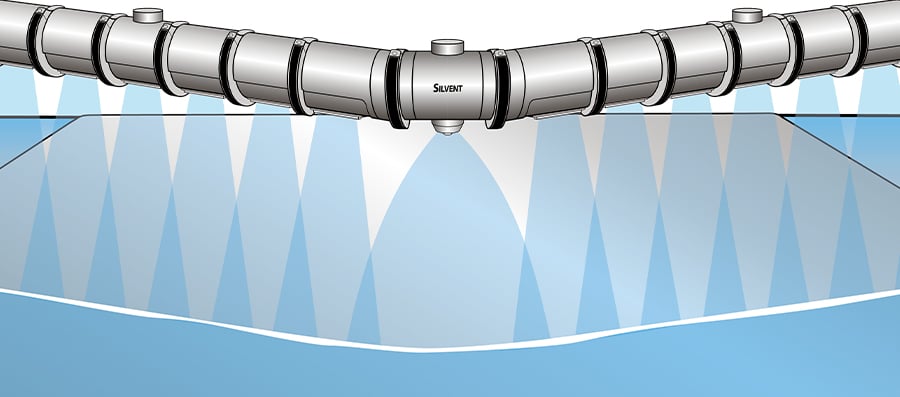

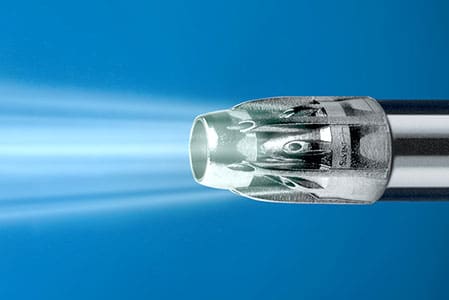

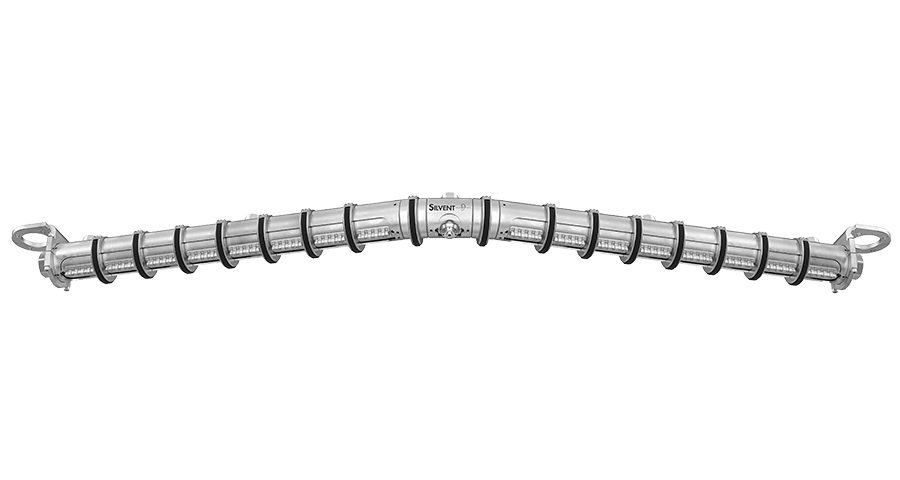

Blowing with compressed air is an effective way of improving the quality of the end product in both hot and cold rolling mills. Compressed air can be used to remove emulsion, water and scale from the surface of the rolled material. It can also be used for cooling and drying. Silvent InTech, Silvent’s global division whose focus is on quality improvements in the steel and aluminium industries, has extensive experience in applications and methods for efficient blowing with compressed air.