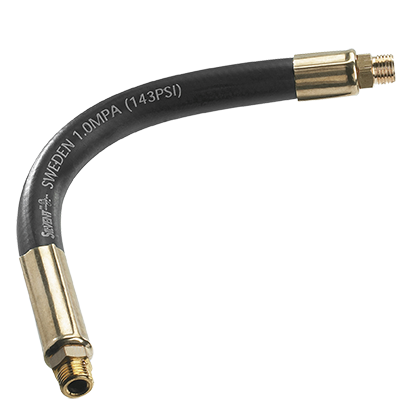

1. Air supply

Regular compressed air is supplied axially.

2. Laval paths

Air flow is rotating more than 1 000 000 rpm.

3. Exhaustion

Warm air exhaust.

4. Energy transformation

Heat energy is removed from the inner air swirl.

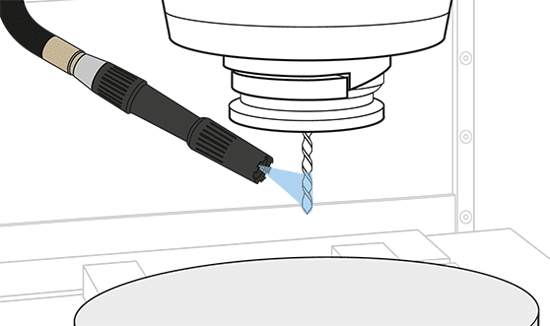

5. Laminar cold air flow

Cold air is discharged from the front at a low noise level.