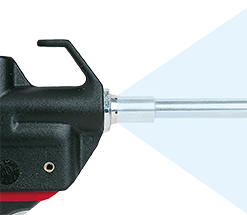

AIR BLOW GUN

SILVENT 500-P

Item number: 05000139247, 05000239247

- Scratch-free PEEK nozzle

SILVENT 500-P: with a PEEK nozzle that prevents unnecessary scratching. The PEEK nozzle has been specially developed for sensitive applications where expensive tools and machines absolutely may not be damaged. The nozzle is fitted on a flexible PA 12 pipe that provides additional protection against scratches caused by mechanical impact. PEEK is a unique plastic material with properties that meet the rigorous quality and safety requirements of, for example, the aerospace industry. It is extremely impact resistant and is capable of handling aggressive chemical environments, strong cutting fluids and temperatures of up to 260°C (500°F). The nozzle is designed with a central hole that generates a concentrated air stream. At the same time, the sound level is low and air consumption is reduced. The PEEK guns are available with three different extension pipe lengths.

Noise reduction 15 dB(A)

Energy savings 8.8 scfm

The trigger mechanism requires a pressure of only 7 N (25 oz), which means that the gun can be used frequently without the risk of taxing muscles. The average finger strength of men is 96 N (339 oz) and of women, 81 N (295 oz). When less than 10% of the maximum strength of a finger is used, no injury arises due to muscle strain.

Ergonomics and precision

The combination of an ergonomic handle and a short trigger for one or two fingers provides a perfect grip as well as the possibility to aim the air blow gun with precision and feeling. The ergonomic design of the handle automatically gives you the optimal blowing position so that you do not need to bend your wrist.

Triggers

Fitted with short triggers as standard to provide the most ergonomic grip. If desired however, they can also be equipped with extended triggers.

Technical data

Benefits when replacing an open pipe

Material specification: Delrin 100P BK602, NBR 70, EN 1.0718, PA12, PEEK 150CA30

Blowing properties at different pressures

Technical data

Benefits when replacing an open pipe

Material specification: Delrin 100P BK602, NBR 70, EN 1.0718, PA12, PEEK 150CA30

Blowing properties at different pressures

Technical specifications

See basic information about the technical data. Read more

Instructions for use

Read Silvent Group General Instructions for Use before you install the product.