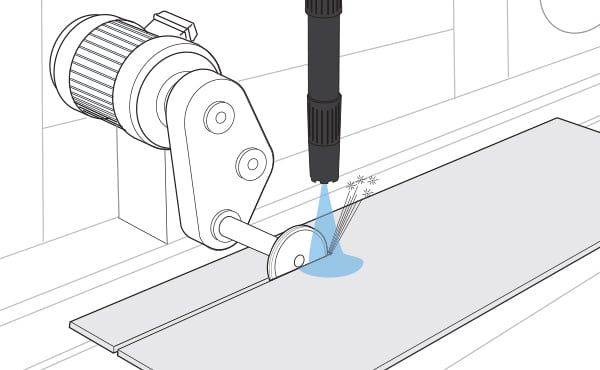

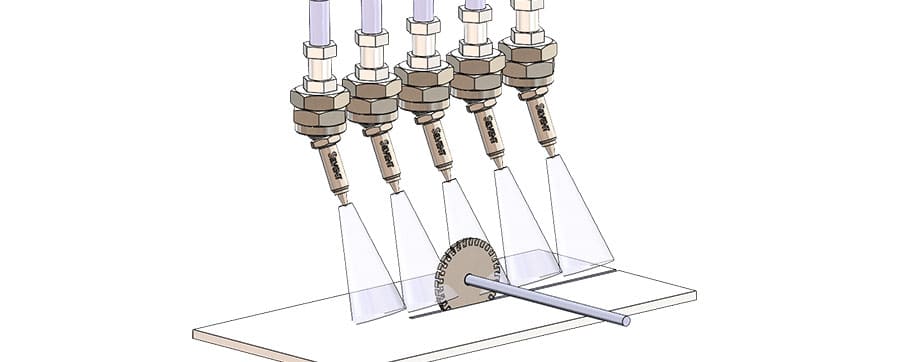

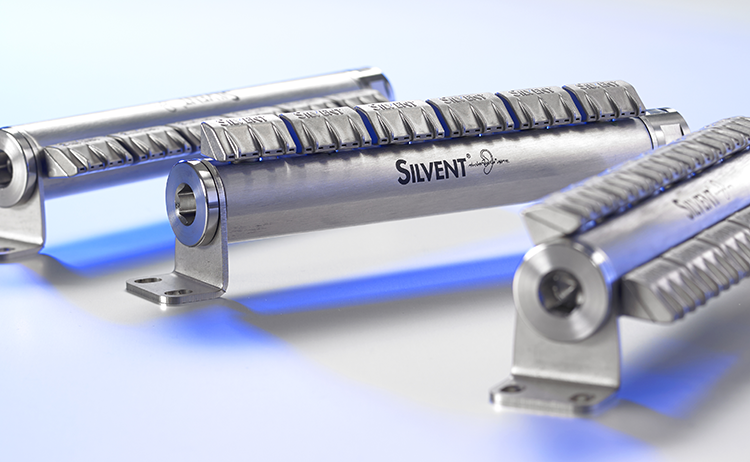

Blowing with compressed air can be a good alternative when cooling, to get an even and controlled process or when avoiding liquid in the cooling process. Silvent has also developed a unique cooling air nozzle, SILVENT F 1, to facilitate fast, efficient spot cooling.

- Nödvändiga cookies låter dig använda webbplatsen genom att aktivera grundläggande funktioner, såsom sidnavigering och åtkomst till säkra områden på webbplatsen. Webbplatsen fungerar inte korrekt utan dessa cookies.

- Cookiebot1Läs mer om den här leverantörenCookieConsentIndikerar medgivande för cookies.

- Hubspot3Läs mer om den här leverantörenembed/v3/counters.gifUsed to implement forms on the website._cfuvid [x2]This cookie is a part of the services provided by Cloudflare - Including load-balancing, deliverance of website content and serving DNS connection for website operators.

- LinkedIn1Läs mer om den här leverantörenli_gcIndikerar medgivande för cookies.

- Stripe6Läs mer om den här leverantörenmDetermines the device used to access the website. This allows the website to be formatted accordingly._abThis cookie is necessary for making credit card transactions on the website. The service is provided by Stripe.com which allows online transactions without storing any credit card information._mfThis cookie is necessary for making credit card transactions on the website. The service is provided by Stripe.com which allows online transactions without storing any credit card information.idVäntande__stripe_midThis cookie is necessary for making credit card transactions on the website. The service is provided by Stripe.com which allows online transactions without storing any credit card information.__stripe_sidThis cookie is necessary for making credit card transactions on the website. The service is provided by Stripe.com which allows online transactions without storing any credit card information.

- hsadspixel.net

hs-banner.com11__cf_bm [x11]This cookie is used to distinguish between humans and bots. This is beneficial for the website, in order to make valid reports on the use of their website. - www.silvent.com1wp-wpml_current_languageDesignates the country code that is calculated based on the user's IP address. Used to determine what language should be used for the visitor.

- Cookiebot

- Cookies för inställningar låter en webbplats komma ihåg information som ändrar hur webbplatsen fungerar eller visas. Detta kan t.ex. vara föredraget språk eller regionen du befinner dig i.

- Hubspot1Läs mer om den här leverantörenmessagesUtkStores a unique ID string for each chat-box session. This allows the website-support to see previous issues and reconnect with the previous supporter.

- Hubspot

- Cookies för statistik hjälper en webbplatsägare att förstå hur besökare interagerar med webbplatser genom att samla och rapportera in information anonymt.

- Google2Läs mer om den här leverantören

En del av de uppgifter som samlas in av denna leverantör är avsedda för personalisering och mätning av annonseringseffektivitet.

_gaGoogle analytics, _ga används för att förstå hur besökaren navigerar runt på webbplatsen_ga_#Used by Google Analytics to collect data on the number of times a user has visited the website as well as dates for the first and most recent visit. - Hubspot4Läs mer om den här leverantören__hsscIdentifies if the cookie data needs to be updated in the visitor's browser.__hssrcUsed to recognise the visitor's browser upon reentry on the website.__hstcSets a unique ID for the session. This allows the website to obtain data on visitor behaviour for statistical purposes.hubspotutkSets a unique ID for the session. This allows the website to obtain data on visitor behaviour for statistical purposes.

- Stripe1Läs mer om den här leverantören1Registers data on visitors' website-behaviour. This is used for internal analysis and website optimization.

- Google

- Cookies för marknadsföring används för att spåra besökare på webbplatser. Avsikten är att visa annonser som är relevanta och engagerande för enskilda användare, och därmed mer värdefull för utgivare och tredjepartsannonsörer.

- Meta Platforms, Inc.3Läs mer om den här leverantörenlastExternalReferrerDetects how the user reached the website by registering their last URL-address.lastExternalReferrerTimeDetects how the user reached the website by registering their last URL-address._fbpUsed by Facebook to deliver a series of advertisement products such as real time bidding from third party advertisers.

- Google1Läs mer om den här leverantören

En del av de uppgifter som samlas in av denna leverantör är avsedda för personalisering och mätning av annonseringseffektivitet.

NIDVäntande - Hubspot1Läs mer om den här leverantören__ptq.gifSends data to the marketing platform Hubspot about the visitor's device and behaviour. Tracks the visitor across devices and marketing channels.

- LinkedIn2Läs mer om den här leverantörenbcookieUsed by the social networking service, LinkedIn, for tracking the use of embedded services.lidcUsed by the social networking service, LinkedIn, for tracking the use of embedded services.

- Meta Platforms, Inc.1Läs mer om den här leverantörenprivacy_sandbox/topics/registration/Väntande

- YouTube21Läs mer om den här leverantören#-#Used to track user’s interaction with embedded content.__Secure-ROLLOUT_TOKENVäntandeiU5q-!O9@$Registers a unique ID to keep statistics of what videos from YouTube the user has seen.LAST_RESULT_ENTRY_KEYUsed to track user’s interaction with embedded content.LogsDatabaseV2:V#||LogsRequestsStoreUsed to track user’s interaction with embedded content.nextIdUsed to track user’s interaction with embedded content.remote_sidNecessary for the implementation and functionality of YouTube video-content on the website.requestsUsed to track user’s interaction with embedded content.ServiceWorkerLogsDatabase#SWHealthLogNecessary for the implementation and functionality of YouTube video-content on the website.TESTCOOKIESENABLEDUsed to track user’s interaction with embedded content.VISITOR_INFO1_LIVETries to estimate the users' bandwidth on pages with integrated YouTube videos.YSCRegisters a unique ID to keep statistics of what videos from YouTube the user has seen.ytidb::LAST_RESULT_ENTRY_KEYStores the user's video player preferences using embedded YouTube videoYtIdbMeta#databasesUsed to track user’s interaction with embedded content.yt-remote-cast-availableStores the user's video player preferences using embedded YouTube videoyt-remote-cast-installedStores the user's video player preferences using embedded YouTube videoyt-remote-connected-devicesStores the user's video player preferences using embedded YouTube videoyt-remote-device-idStores the user's video player preferences using embedded YouTube videoyt-remote-fast-check-periodStores the user's video player preferences using embedded YouTube videoyt-remote-session-appStores the user's video player preferences using embedded YouTube videoyt-remote-session-nameStores the user's video player preferences using embedded YouTube video

- www.silvent.com7sbjs_currentCollects data on user behaviour and interaction in order to optimize the website and make advertisement on the website more relevant.sbjs_current_addCollects data on user behaviour and interaction in order to optimize the website and make advertisement on the website more relevant.sbjs_firstCollects data on user behaviour and interaction in order to optimize the website and make advertisement on the website more relevant.sbjs_first_addCollects data on user behaviour and interaction in order to optimize the website and make advertisement on the website more relevant.sbjs_migrationsCollects data on user behaviour and interaction in order to optimize the website and make advertisement on the website more relevant.sbjs_sessionCollects data on user behaviour and interaction in order to optimize the website and make advertisement on the website more relevant.sbjs_udataCollects data on user behaviour and interaction in order to optimize the website and make advertisement on the website more relevant.

- Meta Platforms, Inc.

- Oklassificerade cookies är cookies som håller på att klassificeras tillsammans med utfärdarna av enskilda cookies.

- Meta Platforms, Inc.1Läs mer om den här leverantörentopicsLastReferenceTimeVäntande

- Meta Platforms, Inc.

Lagen säger att vi får lagra cookies på din enhet om de är absolut nödvändiga för att kunna använda den här webbplatsen. För alla andra ändamål krävs ditt medgivande.

Denna webbplats använder olika typer av cookies. Vissa cookies placeras ut av tredjepartstjänster som visas på våra sidor.

Du kan ändra eller dra tillbaka ditt samtycke till cookie-förklaringen på vår webbplats.

Läs mer i vår sekretesspolicy om vilka vi är, hur du kontaktar oss och på vilket sätt vi behandlar personuppgifter.

Ange ditt samtyckes-ID och datum för när du kontaktade oss gällande ditt samtycke.