Silvent technology – a revolution in pneumatics

Silvent’s patented blowing technology, known as Silvent technology, utilizes engineered laminar air jets to minimize air turbulence usually caused when blowing with compressed air.

Silvent’s patented blowing technology, known as Silvent technology, utilizes engineered laminar air jets to minimize air turbulence usually caused when blowing with compressed air.

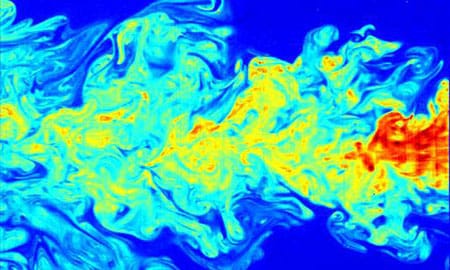

Turbulence refers to flows that are disorganized and fluctuate at different speeds and angles, creating pressure variations in the air. These pressure variations equate to sound and it is precisely these variations that cause the eardrum to vibrate. Silvent technology reduces sound levels. The technology reduces the intensity of the turbulence in the airflow and generates most of its sound in a frequency range higher than that which the human ear can perceive or be harmed by. When the intensity of turbulence is reduced, more of the energy input is converted into directed kinetic energy. This reduction in losses to turbulence leads to lower energy inputs to maintain blowing force.

The design and shape of the nozzle also means that some of the air surrounding it is drawn with relatively little resistance into the air jet providing a greater blowing effect. Thus, the reduced turbulence, higher frequency and co-ejection of the surrounding air lead to a reduction in sound level and energy input while providing energy-efficient blowing force. Every part of a Silvent air nozzle is designed to optimize the combination of blowing force, energy consumption and noise levels.

“The design, location and discharge angles of Laval nozzles are intended to optimize the conversion of the compressed air’s potential energy into directed, concentrated kinetic energy.”

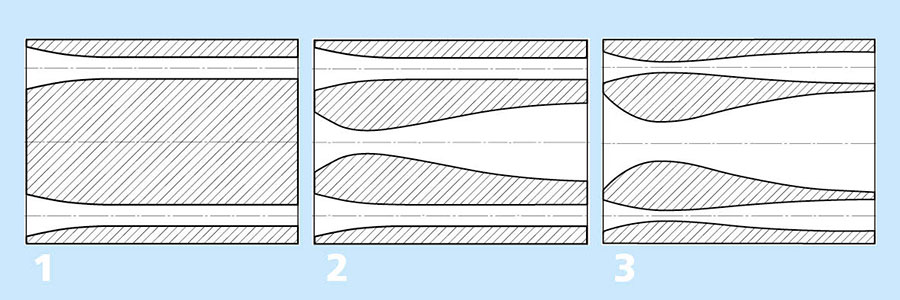

1. Silvent’s first patent was based on air flowing and expanding through multiple aerodynamic holes generating parallel air streams, creating laminar jets. This has formed the basis for all further development of the Silvent technology. The next development step was to replace the holes with slots. This allowed greater discharge areas to be achieved and thus higher blowing forces. By using the aerodynamic holes, the laminar jets and low sound levels could be maintained, as could the efficient use of compressed air.

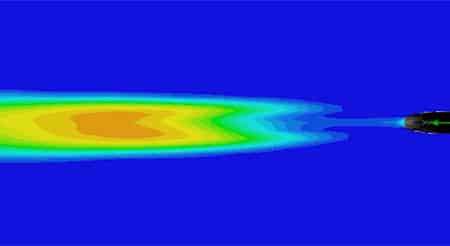

2. Since then, Silvent has patented many technologies including one based on a combination of existing Silvent patents. This technology incorporates a central Laval nozzle creating a supersonic jet at the core, flowing parallel to peripheral jets. The compressed air’s entire energy is transferred into kinetic energy without the core jet expanding sideways. The peripheral jets prevent the core jet from being impeded by the surrounding air, allowing it to be used to full effect and at greater blowing distances.

3. In terms of manufacturing, Silvent’s latest generation of patented air nozzles are complicated products that not only include a central Laval nozzle, but also where the entire discharge series is based on Laval technology. Each Laval nozzle works together with the others. The design, location and discharge angles of Laval nozzles are intended to optimize the conversion of the compressed air’s potential energy into directed, concentrated kinetic energy. This results in a unique combination of fully utilized compressed air and the lowest possible sound level.

Today, Silvent has a number of air blow guns – Pro One, Pro One+ and 767-L – that are equipped with the new generation patented air nozzles. The air blow guns have characteristics that would have been impossible to provide just a few years ago. In order for the work to be as efficient as possible, all research, development and product development at Silvent takes place in close collaboration with key customers.

We’ll be glad to help you with a proposal to improve your application. Begin by answering the 8 questions below and we’ll get back to you as soon as we can.