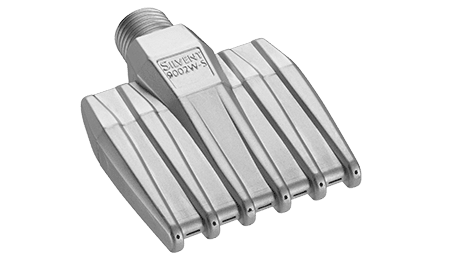

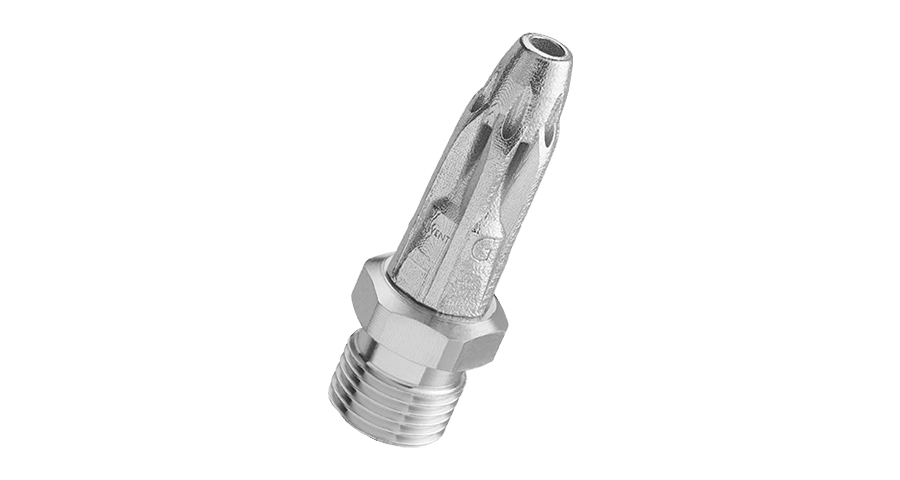

Air nozzle for quiet, efficient blowing with compressed air

Air nozzles are commonly used for blowing with compressed air in industry when e.g. cleaning, drying, cooling, sorting and transporting objects.

Silvent’s air nozzles have three unique advantages

Few industries are aware of just how much their compressed air actually costs. Producing compressed air is expensive, which means it’s important to use it in the best possible way. Silvent’s air nozzles optimize energy use and enable quiet and efficient blowing with compressed air.

Reduce energy consumption by 35%

Many manufacturing industries use open pipes for blowing with compressed air. While they often do the job, they are an expensive and inefficient solution. Open pipes usually create a great deal of turbulence when blowing with compressed air, which is extremely energy intensive. Thus to use compressed air in an energy-efficient manner, it’s important to minimize turbulence. This is easily done by installing an air nozzle.

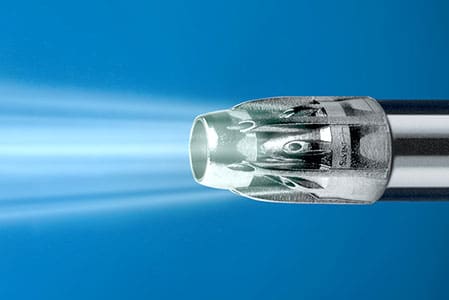

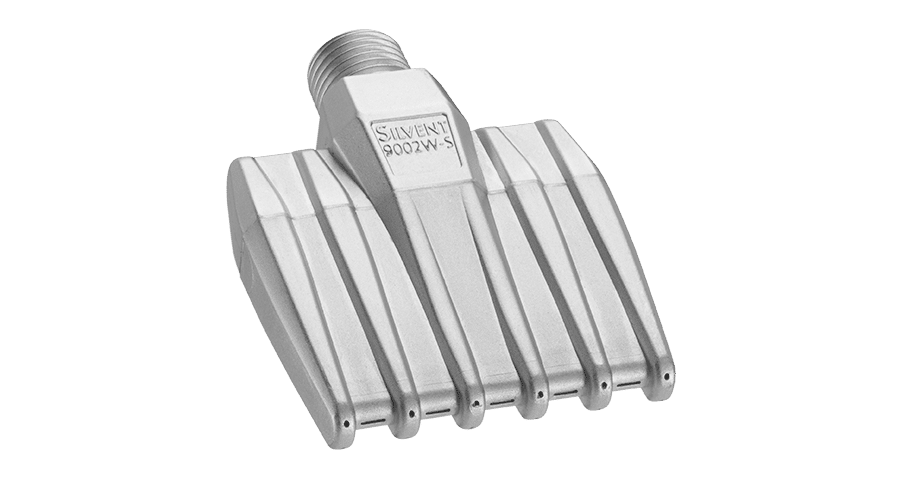

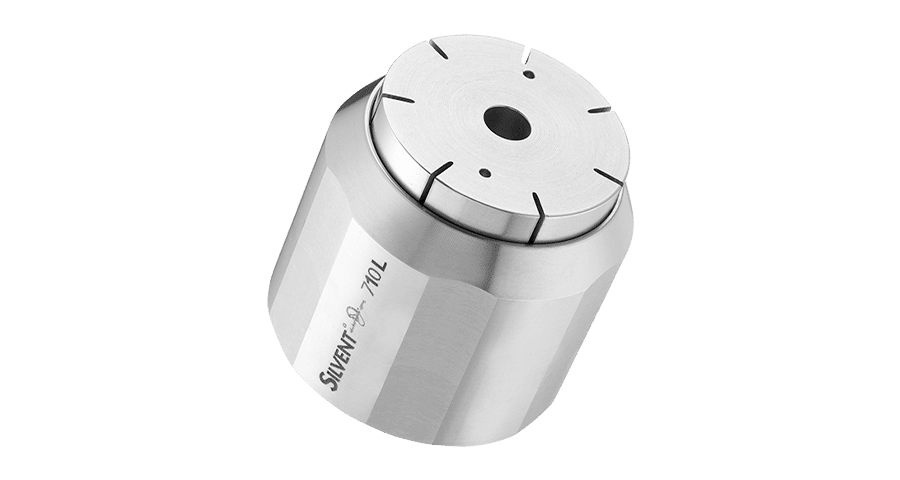

Silvent’s air nozzles for blowing with compressed air are specially designed to optimize energy use and create a uniform, smooth and straight so-called laminar air jet. The design reduces turbulence and gives rise to entrainment, which means the compressed air draws the surrounding air with it. When less energy is wasted producing turbulence, a greater part of the energy input can be used for blowing with compressed air. This makes for more energy-efficient blowing, and the installation of a Silvent air nozzle can reduce energy use by up to 35%.

Reduce the sound level when blowing with compressed air

Blowing with compressed air often leads to high sound levels in industry. One reason for this is the use of open pipes when blowing with compressed air. Open pipes create turbulence that generates high sound levels. Noise and high sound levels are not only harmful for people working nearby the blowing application, but also affect concentration and the overall perception of the work environment. There are therefore many advantages in reducing the sound level in industry. To reduce the sound level when blowing with compressed air, all open pipe should be fitted with air nozzles.

Silvent’s air nozzles reduce the sound level when blowing with compressed air compared to blowing through open pipes. This is due in part to the reduction in noisy turbulence from using Silvent’s air nozzles, and also because of the nozzles’ special design. Silvent’s air nozzles pass the compressed air through small holes and slots, which raises the sound to frequencies beyond what the human ear can perceive. This allows us to make blowing with compressed air both quiet and efficient.

Improve the efficiency and the manufacturing process

The turbulence that occurs when blowing with an open pipe affects not only the energy consumption and noise level, but also the blowing force. This has a negative impact on the final result. Most of our customers contact us because they have problems with their existing solution and need help improving their manufacturing process. Flaws in the manufacturing process can, in the worst case, have a negative impact on the quality of the final product.

Unlike an open pipe, Silvent’s air nozzles minimize the turbulence and generate a strong and efficient blowing force. Silvent has a large range of air nozzles, which makes it possible to adjust the solution to the specific application and the customer’s goals, for the best possible results. Silvent’s representatives will be happy to help you find the right solution for your application.